Most

businesses have many different risks to manage every day. So minimising

exposure to these is crucial for business survival and success. For many

procurement professionals, the risk management ‘game’ has new rules and a

playing field that is complex and global.

Supply Chain Concerns

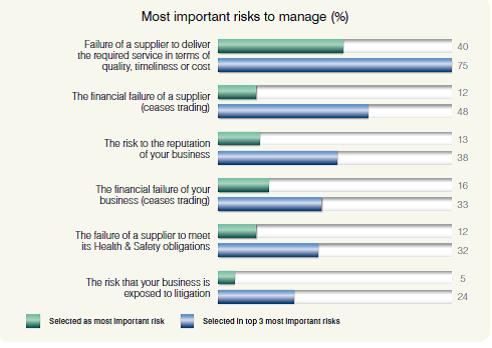

According to Supply Risk & Compliance research conducted by Achilles in

2015, 40% of businesses say that their biggest risk through the procurement

process is that the supplier will fail “to deliver in terms of quality,

timeliness or cost”. This is consistent for all sizes of organisation and

across all the sectors that were surveyed, with 75% of respondents putting this

in their top-three risks to manage. There is an obvious and immediate impact on

the business if the supply chain fails in terms of product quality, timing or

service delivery.

Irrespective of sector, large companies are concerned about protecting their

brand and reputation from damage caused by weak or high-risk links in the

chain. Smaller companies have concerns closer to home and are focusing their

energies on financial survival.

Nearly half (48%) of the companies surveyed were concerned about the financial

failure of suppliers’ businesses and elevated this to the top-three risks they

have to manage. In addition, 33% list the financial failure of their own

business in their risk top three. In the construction industry, 30% of those

surveyed put failure of their own business as the number-one risk.

Costs of Supply Chain Failure

In the independent Supplier Risk & Compliance research project commissioned

by Achilles in 2014, aggregated results from across all industries show that

supply chain failures cost the manufacturing sector £58-million during 2013.

That includes: the cost of suppliers failing to deliver on time; deliver the

required service in terms of quality; financial failure of a supplier; effect

of natural disasters and severe weather; damage to reputation due to a

supplier; failure of a supplier to meet Health & Safety obligations;

industrial action; exposure to litigation due to a supplier; and acts of

terrorism or conflict.

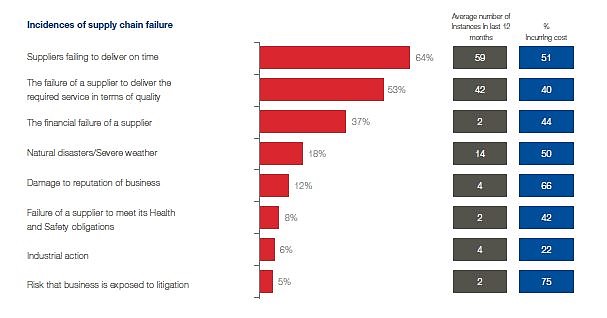

The most common cause of failure is a supplier failing to deliver on time,

experienced by 64% of those surveyed. Just over half (53%) experienced an issue

with suppliers failing to deliver products of the required quality; 34% of whom

incurred a cost. And ranking third in the most common causes of failure is a

supplier going bust. One third (37%) experienced the financial failure of a

supplier, with 44% paying a financial price.

Contributed by:Andrew

Hillman is Managing Director of Bespoke and Publishing Editor

of Bespoke Procurement Bulletin

http://www.bespoke.co.za/blog/88905-supply-chain-failure-and-associated-costs-by-andrew-hillman