When tackling an optimisation project, many mistakes are repeatedly made because of misconceptions which exist in the industry. This article intends to discuss and dispel some of those misconceptions.

1. Dynamic routing is always preferable to static routing

The creation of static or master routes has lost favour recently with many companies trying to implement dynamic routing. While dynamic routing, if performed properly, can reduce transportation costs the benefits of master routing should not be overlooked. Many of these advantages are difficult to quantify but can be significant.

· Master routing achieves more predictable customer service- stores can plan to have staff available to stock shelves since the arrival time at store is predictable and order placing is more routine.

· Driver familiarity with routes and is increased- stores often insist on being delivered to by the same person because of security reasons, goods handling and familiarity with the stores’ receiving environment.

· The warehouse picking process is simplified and more efficient due to standard, repeatable procedures for loading vehicles.

· Master routing provides a platform for re-optimizing routes with minimal interruption when new stores are added, existing ones close or service frequencies and requirements change.

· For certain industries, dynamic routing would not make sense -in the often cited waste collection application, it is important for people to know what day bins should be put out and this day should not change often.

· Master routes can be inflexible, more costly and inappropriate when demand rates vary a lot but this does not mean that they are always inferior to dynamic routing.

2. When creating static/master routes, balancing volume or number of drops should be the objective

Each customer which must be visited has a different offload time, order size and frequency and the

travel distance to each store is different. If the assignment of customer visits to days is done without

consideration to the geographic location of the customers and the potential routes to which they can be assigned, the total distance travelled and time worked could be extremely high. The objective of a master routing (and/or nominated delivery day exercise) should be to balance workload – i.e. total time worked which includes drive time and time at store. This will ensure even fleet utilisation across the week (or any other length planning period). Usually, the total volume and number of drops per day are fairly balanced as a result.

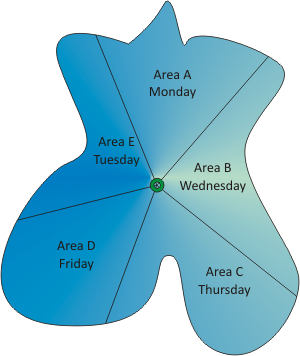

3. When creating static/master routes, sending all vehicles to a single area each day is optimal

Many people are under the impression that assigning customers to fixed visit days, for a week-long period for example, means simply dividing up the service region into five areas as shown below. This is not an optimal strategy for many reasons. Firstly, should there be an emergency order or re-delivery for a customer in Area A on a Thursday then a vehicle will have to go north of the depot for a single delivery as all the day’s deliveries are south of the depot.

Secondly, sales representatives typically visit customers to take an order a day or two before the delivery is made. If a sales rep lives in Area E for example, s/he would have to visit all the customers in that area on Friday or Monday. This is probably not do-able in terms of time or travel distance and leaves no work for the other three days of the week. The only solution would then be for her/him to service customers in other areas, thereby increasing the total kilometres travelled per week and reducing the number of visits made because of increased time spent in the car. Finally, if there are five routes in Area B for example, then doing all five routes on one day or doing each route on a different day of the week does not change the total hours worked or kilometres travelled. Thus it is far better to have vehicles in more than one area on each day of the week.

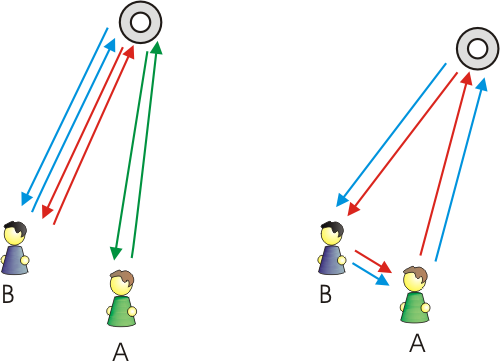

4. All things equal, improving customer service (more frequent visits) means increasing cost

Particularly with remote or outlying customers, if at least one customer in an area has a minimum required visit frequency, then all customers in that area should be assigned to common visit days. This ensures that the area is visited the minimum number of times necessary. In the diagram below, customer A (currently serviced once per week on a Wednesday) could be moved to the same visit days as customer B (serviced twice per week on Tuesday and Friday). The incremental cost of visiting customer A twice is small compared to the savings obtained by not going to this area three times per week. Customer A could even be offered a discount to change visit day.

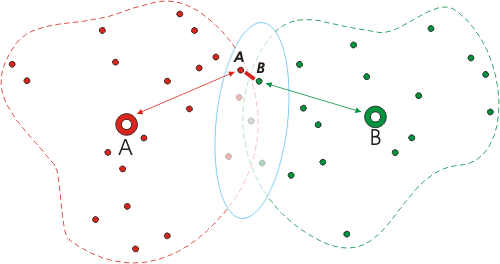

5. Assigning customers to the closest depot ensures the minimum total distance is travelled

In the diagram below, the band of customers which have been shaded red are closer to depot A and those in green to depot B. The customers in the purple region are marginally closer to the one depot than to the other. Consider a vehicle doing a single round trip from depot A to customer A and driving 100km. Depot B might send a vehicle on a similar trip to customer B and travel 120km. The 2 customers are only 5km apart. Had a single vehicle been sent from depot I to service both customers, the total distance would be 110km. Ideally, the decision of which depot to service a customer from should be made each time the customer needs a delivery so that other customers requiring a delivery can be considered in the decision.

Contributed by: Rick de Klerk, Technical Writer, Opsi Systems