I am constantly amazed that an automotive manufacturer will design and market vehicles with top-end speeds of 250kph+ MPH and 0-100 speeds in the sub 4 second range. Don’t get me wrong, I own three vehicles with 5.7L Hemi engines so I love powerful vehicles. However, considering the top legal speed in most of the countries is 120kph and most stop and go driving takes place where speed limits are less than 70kph, a driver rarely gets the opportunity to experience a vehicle’s true performance.

Viewing unconstrained versus constrained vehicle

performance is similar to what supply chain professionals deal with when

planning the supply chain. Today, many supply chain planning processes

only consider unconstrained supply capabilities. The plan assumes any demand

for a product or service can be met. There are no constraints. Maybe on the

autobahn in Germany, this unconstrained view makes sense, but when speed limits

or constraints exist, what is feasible is more important to synchronizing and

aligning your end-to-end supply chain.

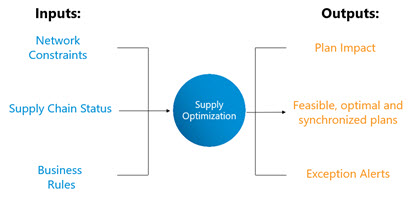

The objective of constraint-based supply

planning is to derive an optimal time-phased replenishment plan for all

item/locations that achieves desired customer service while respecting

inventory policies and real-world constraints at all echelons of the supply

chain. The inputs to constrained supply planning include supply chain

constraints, supply chain status and business rules. Constrained supply planning

provides supply chain KPIs, exception alerts, feasible supply plans, and the

planned purchase orders, transfer orders, production orders and VMI orders

required to execute the plan. Constraint-based supply planning is vitally

important because it provides a feasible plan that is actually executable.

There are three main types of constraints to

consider when developing a feasible supply chain plan; Production

Constraints, Flow Constraints and Storage Constraints. These three types of

constraints should be determined at every point along the extended supply chain

to ensure an optimal and feasible supply plan. This leads to the need to

consider many constraints including:

Building and

maintaining a comprehensive constraint-based supply chain planning capability

is an evolutionary process. To be successful it is best to start small and

build towards more mature capabilities. Most companies that build

constraint-based supply planning capabilities have already developed

functioning demand planning and inventory planning. Many of these will also

take the intermediate step to develop an unconstrained supply planning

capability first before moving forward with constraint-based planning. Taking a

crawl, walk, run approach builds experience to determine what capabilities are

important and provides time for supply chain personnel to grow and learn at an

appropriate pace. The key though is to get the journey started towards

constraint-based supply planning.

The ultimate goal of a supply chain organization

is to meet customer requirements while minimizing total supply chain costs.

That can only happen by considering the entire end-to-end supply chain as an integrated

system and optimizing that system. This was not possible just 10 years ago, but

today it is due to improvements in computing power and the availability of next

generation supply chain planning systems. Developing a constraint-based supply

planning capability may seem daunting. However, keep in mind that companies

that take this journey see significant improvements in customer service and

reductions in total supply chain costs while taking a giant leap towards

optimizing their supply chain.

Where are you in your journey to

constraint-based supply chain planning?

Article contributed by Logility. The original article can be

found at www.logility.com