Cost-effective and accurate order fulfilment is more important than ever. And a small investment in one thing can have a big impact on both—investing in your people. It is not uncommon for a labour improvement program to yield increases in accuracy and productivity from 30-50% and decreases in labour costs from 25-40%. Follow these seven steps to create a well-managed and motivated workforce.

Table:

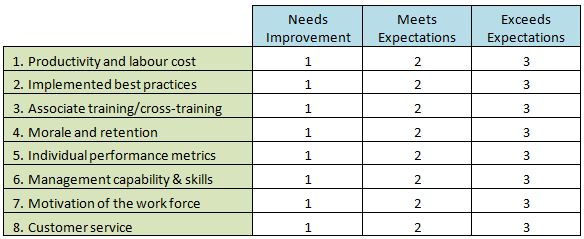

Do a quick evaluation of your distribution centre and see if these Seven Keys to Organizational Excellence might help your distribution centre operations.

1. Mindfully Redesign your Operations

The distribution operations at many companies have unravelled over time. Job descriptions don’t exist. Organization charts have holes. Procedural documentation is lacking. Associate to management staffing ratios are high. Policies are not documented or communicated. Training and orientation programs are inconsistent. This is particularly true with fast growing, successful companies who are too busy executing to worry about efficiency and effectiveness. They find that many of the basic components of organizational design and structure are lacking.

It may be time to go back to the basics – to formally assess and redesign your operations. Start by getting input from a variety of company stakeholders, including operations, human resources and finance (for policies regarding pay). Review your policies, procedures and organization structure. Develop standards and roll out the refreshed model with thorough communication and training.

2. Simplify and Standardize your Work Processes

Sound processes are the foundation of efficient distribution. Inefficient work methods and non-value-added activities need to be minimized or eliminated. Use whatever method you choose (TQM, Lean, Six Sigma) to re-evaluate and improve your processes. Then communicate these “best practices” to associates in a way that they will be adopted. To increase ownership, consider conducting brainstorming sessions with associates, supervisors and managers to solicit their ideas. And document processes and conduct training to reinforce and educate.

3. Invest in Training

It takes 30 days to establish a habit. Granted, many DC operations are simple and straightforward (e.g. unloading and loading). But good training also includes the sequence of tasks, the technology to support the task, and the best method of performing the task. “Best methods” should be developed by your top performers and shared with all. Consider cross-training associates to more effectively share labor talent across the facility. And keep in mind that associates will need to occasionally work in the operations they are cross-trained, or they will lose proficiency.

4. Implement Labour Management Software

For many companies, productivity tracking is still done with a spreadsheet and consists of basic metrics like departmental and facility-wide units-per-hour, cost-per-unit, and direct/indirect labour hours. While these metrics are adequate for measuring overall performance, they do not track individual performance or effectiveness, nor do they allow for individual feedback. This level of visibility is imperative to effectively manage labour. And accurate tracking at the individual level can be used to plan and balance staffing by operational area, making best use of available labour assets throughout the course of the day.

In the past, collecting the data to track individual performance required self-declared time and production tracking via time cards, production sheets and reports. But advances in technology have reduced the administrative burden and automated the collection of data. Most WMS vendors offer Labour Management Software (LMS) modules that are integrated into their WMS or an ERP.

5. Publish Labour Standards

Everyone needs a goal. Engineered, multi-variable labour standards are an objective tool to measure individual or team-based performance and are necessary to accurately reflect work content in distribution operations. When setting performance goals, it is important that they are perceived by the associates as being realistic, fair and accurate, or they can negatively impact morale, productivity and retention.

There are several methods of developing standards, including time and motion studies, MOST and master standard data (MSD). There are pros and cons to each method, but the output is the same—standard allowed minutes (SAM’s). SAM’s are a time measurement for the tasks that are being performed—the standard goal time for the operation. By developing accurate and fair standards, you can set one performance goal facility-wide: 100% Performance.

6. Get your Managers to Lead

Most managers are trained to manage administrative tasks and to solve problems that occur. But many managers are not well equipped to LEAD their people. Instead, they spend their time tracking the status of orders and waves, attending meetings and answering email messages – all from the convenience of their office. “Floor presence” is becoming a lost art form, as is spending time mentoring, motivating and coaching associates. Goal setting and performance review are reserved for the annual review process.

Managers need to lead, and they need to have daily contact with their people. They need to be knowledgeable of their operations at a detailed level. They need to be vested in their associates’ performance and to remove roadblocks to high performance. They need to be trained in “soft skills,” such as coaching techniques and change management. And they need to have their performance linked to their people’s performance.

7. Reward your People

People will respond when there’s “something in it for me.” But to create a high performance environment, you will need several forms of motivation as people are not all influenced in the same way. The three main forms of motivation include recognition, rewards and incentives—and they are most effective when used together.

Recognition programs can be public or personal, but require personal interaction between management and associate. This can include a “pat on the back” or being honoured at a town hall meeting. Reward programs can be individual or team-based and are usually characterized by giveaways, raffles, tickets, or company sponsored lunches. Incentive programs, also known as “pay-for-performance,” motivate associates by paying them a bonus based on their performance against a standard. Incentive programs are typically self-funding in that the labour savings generated by the increase in productivity is shared with associates. It is very common that the labour savings exceeds the incentive payments, creating a positive cash flow situation.

Summary

Workforce improvement projects typically yield a high return on their investment. And they impact quality and accuracy as well. Focus on these areas when undertaking a project to improve workforce performance.

1. Organizational development and readiness

2. Lean processes

3. Training and cross-training

4. Labour management software

5. Labour standards

6. Leadership Skills

7. Motivation

The sequence is important. For example, develop incentive pay systems after developing labour standards and implementing an LMS. Similarly, don’t develop labour standards without first improving processes and training associates.

Contributed by Marc Austin, Managing Director Fortna EMEA (Pty) Ltd