“Who designed this supply chain?” …A common question from senior executives when confronted with an end-to-end view of their supply chains! The fact is supply chains for many of the world’s largest and best-known companies are as much historical accidents as they are intentionally engineered systems.

A simple mapping and visualisation of supply chain flows, manufacturing footprints, customer fulfilment, sourcing locations, and inventory stocking locations can often point out key disconnects and create head-scratching moments. Why is this product being produced here? Why are materials sourced from Region A, produced in Region B, then air-shipped as finished product back to Region A?

What is often just as perplexing is that most of these companies spend millions or even hundreds of millions of dollars on the implementation of Enterprise Resource and Advance Planning Systems. Enterprise Planning Systems may automate the existing supply chain, but that doesn’t change the fact that the end-to-end supply chain operation may at best be sub-optimal or at worst, broken altogether.

Many companies have focused on efficiency and in many cases their supply chains have never been designed, they have simply grown and developed on a piece meal basis. Within this scenario companies seek to drive improvement and this really gives them an efficiency focus. They have had to make short term decisions that were right at the time but over a period of years simply do not work for them and this has resulted in supply chains that are fundamentally flawed. Being more efficient can be very negative if you are doing something wrong in the first place, as you simply compound your problems by becoming more efficient at it.

It is in fact the “design” of a supply chain that sets the true potential of what can be achieved across all key metrics including cost, service, sustainability, and risk. Given the new global reality of volatility, complexity and rapid change, supply chain design has become a critical business function. Forward-thinking businesses are continuously redesigning and improving their supply chains by using modelling technology to examine how their supply chains will perform under a wide range of market conditions and assumptions and analysing the trade-offs of cost, service and risk

Why Is Supply Chain Design Important?

The modern supply chain is an increasingly complex network that often stretches across continents and supports numerous market segments. With this complexity, the impacts of change are harder to determine and the risks involved with being unprepared grow higher.

Volatility is also near constant in the business world today. Changes in demand, shifts in commodity prices, supply disruptions, variability in transportation availability, natural disasters, geopolitical change, and regulatory issues all impact the flow of goods to market.

Companies with supply chains built with only blue sky scenarios in mind are massively impacted when that clear weather takes a turn for the worst. Supply chain design enables companies to create accurate models of their end-to-end operations to engineer a better plan and to explore how potential changes affect service, costs, sustainability and risk.

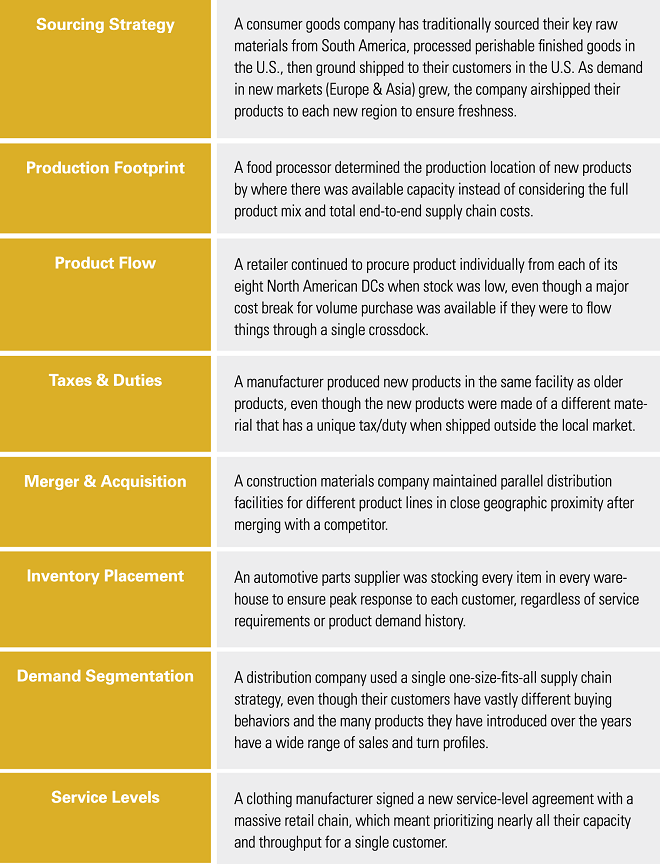

The following are real-world examples of supply chain decisions that are made throughout the course of doing business which often lead to sub-optimal operations.

Contributed by Rod Stout, Business Modelling Associates